Mainly two types of joint design are employed in diaphragm walls. Shoring structures are completely different from retaining walls as this is.

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

The density of bentonite is low compared to concrete hence is replaced during the concreting.

. At the conclusion of the chapter a summary of the field application methods and the. Shoring in Construction is essentially required to support a deep excavation to prevent the retained soil from overturning and eventually causing a project mishapIts support requirement depends on the types of soil and when an excavation depth at least 120-meter difference in levels from ground level. The annular space should be sealed vertically from the rock or screen setting to the surface with either bentonite clay or neat cement grout in the manner described in C or D above.

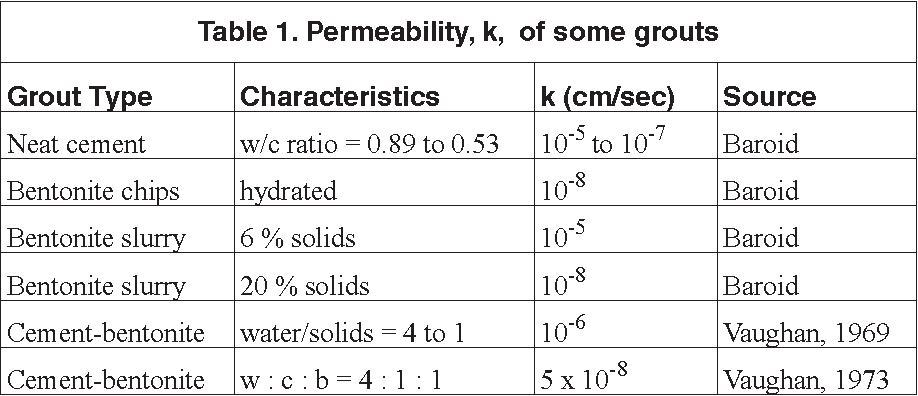

Cement-bentonite slurry walls also provide another alternative. The design of the stabilizers and the appropriate dosages to enhance soil properties to certain prescribed levels as well as the laboratory mix design methodologies are discussed. The unit easily mixes and pumps slurries of Portland cement fly ash bentonite and lime flour.

They are by using. Also one should check that used bentonite slurry and soil-bentonite slurries are able to withstand chemical attacks from the insitu soils. Earth Retaining Systems in Deep Excavation.

All controls are conveniently located on the operator platform for easy one-man control. Field construction practices along with quality control and assessments followed are also mentioned. Pump Pump Type 316 progressing cavity OutputPressure variable up to 20 gpm 261 psi Colloidal Mixer Mix Tank 130 CF with bottom clean out Mixing Pump 2 x 3 x 6 diffuser- type.

In such a case alternate slurry materials such as attapulgite and. The bentonite clay displaced is collected and reused. In this method the trenches are excavated under a slurry that later solidifies and create the permanent barrierbackfill.

Wells drawing from unconsolidated water-bearing formations should be fitted with screens having the maximum open area consistent with strength of the screen and the size of.

Pdf Cement Bentonite Grout Backfill For Borehole Instruments Semantic Scholar

Soil Cement Bentonite Slurry Walls Geo Solutions Soil And Groundwater Problems Solved

Mixture Designs Proportions Of Plastic Concrete Mixes Download Table

Blend Mix Proportions And Blend Slurry Properties Download Table

Design Proportions For Sccb Mix Design Program Download Scientific Diagram

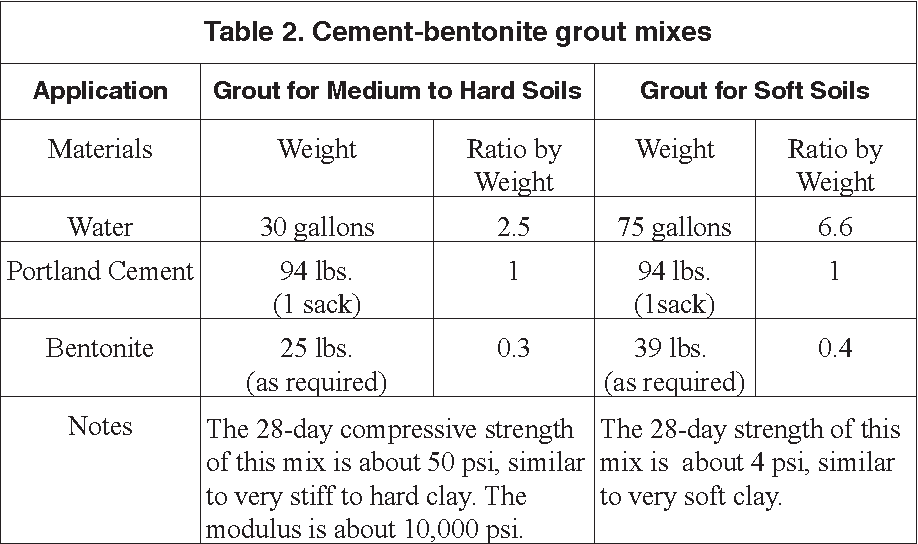

2 Summary Of Cement Bentonite Grout Ratios Download Scientific Diagram

All You Need To Know About Bentonite In Cement Slurries Better Well Cementing For All

Concrete Mix Design Used For Laboratory Tests Download Table

0 comments

Post a Comment